Management System

SAE is gradually developing and improving its management systems at the pinnacle of industrial tools & technology in area: Quality, Health-Safety-Environment, Information security, Information & Technology, and Integrated Operations Management Systems.

Quality Management System

As a professional EPC company, SAE is continuously working to reach and maintain full compliance of national and international standards, such as: ISO9001 and ISO 14001.

Health, Safety and Environment Management System

SAE is remain fully committed becoming a recognized industry leader in process safety management, applying good design principles, engineering, operation & maintenance practices to manage our executions & operations safely by implementing the SAE Operating Management System covering all areas from process safety to personal health, and environmental aspects.We are comply to OHSAS 18001 and SMK3.

Information Security Management System (ISMS)

Information is an asset which likes other important business assets, has value to our organization and hence need to be properly secured.

SAE very concern security of the information either property of SAE, Customers/Clients and Partners, therefore SAE has established and implement Information Security Management System (ISMS) which comply to International Standard ISO 27001:2005 to rise the confidence either SAE, CUSTOMER/CLIENT or Partner.

The objective of Information Security Management System is to ensure business continuity of critical processes and minimize business damage by preventing and minimizing the impact of security incident.

The ISMS is subjected to all assets and shall be applied to All SAE employees on each business processes within SAE's Home Office, Branch Office, Project Office, and Site Office where include customers, partners and visitors who entering or accessing or working at those places and/or SAE's assets. SAE’s ISMS, has adopted the PDCA model (Plan, Do, Check, Action) for managing the Information Security function.

Information Technology System

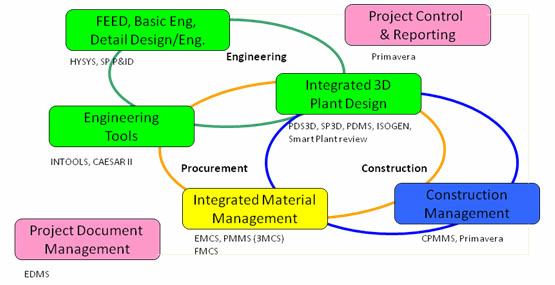

In SAE, Information & Technology (IT) takes an important role to enable us to work integrated, efficiently & accurately, real time and finally contributing in excellent outcomes. Our IT support systems featured the latest computer technology with modern software applications for engineering, 3D plant design, project planning & control, material management, construction management, and project document management, as well as high speed data communication via LAN and VSAT.

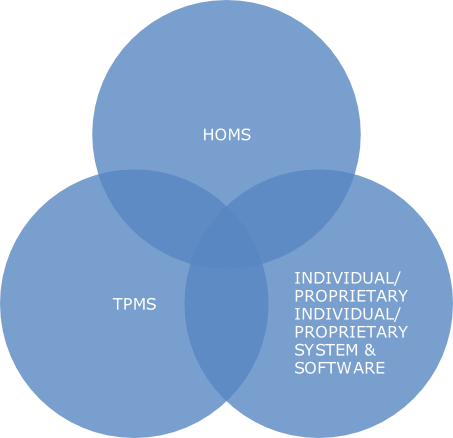

Integrated Operation Management System (IOMS)

To integrate our Operation Management System, SAE’s IOMS has developed and establish. This integration are among SAE’s HOMS (Home Office Management System), TPMS (Total Project Management System) and Individual/Proprietary System & Software.

TPMS is developed and established to maximize operation and Management of Project from Proposal state to Execution Stage by integration and collaborative system with powerful tools and system so that project can be execute properly, efficiently, accurately and real time to reach Project and Company goal.

The TMPS will consist of the following Modules :

- Cost Estimation

- Schedule Management

- Engineering Management

- Document Management

- HSE Management

- Procurement Management (Including E-Proc)

- Material Mgt Monitoring and Control (Including EMCS & FMCS)

- Cost Control Management

- Construction Management

- Pre-commissioning&Commissioning Management

- Reporting (Including Dash Board System)